The objective for Day 8 was dog holes ! Planning, reviewing the BenchCrafted web site, finding materials, making the jig, testing the jig and finally cutting the dog holes in the top piece.

Before actually cutting the dog holes, I had to stop and figure out the placement of the alignment dominos I have been using on each of the top sections. This was a little tricky since I did not want dominos in dog holes. Also on the tail end of the bench I only had 2″.

Thanks to Benchcrafted for the Pictures and Video for the dog hole jig. It was a process to take their pictures and comments and create a jig for my bench build.

The most important thing is to cut the dog holes in the correct direction. The top of the hole is the larger space and the slant goes towards the tail vise.

Big advice. Make a full size pattern for the dog hole. It will help you keep your orientation for the direction and angle slant.

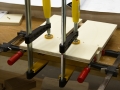

Making the dog hole jig was an adventure. I always have 3/4″ SandePly ( Home Depot ) scraps. Also used some scrap 2×4 left overs. I used my excellent WoodPeck 12″ Sliding Bevel Gauge. It was the perfect tool for marking and checking the 2 degree angle.

I used my two Dewalt 618 routers.

The plunge base with a Bosch 1/2″ x 1 1/4″ 3 flute upcut sprial bit and a pattern collar. This was used to hog out all but the last 1/8″ of material. Using the plunge settings this was done in two passes.

The fixed base with a Pat Warner Offset subbase and a Whiteside Ultimate Pattern/Plunge Compression Bit, 7/8 Cutting Diameter, 1 1/8 Cut Length. This was the final finish cut. I was NOT disappointed.

So here it is. Video of me cutting a dog hole. 2 minutes. After 2 hours of building jig, testing and clamping.

On to day 9.

Bench Build Blog Index

Please enjoy the full set of day 9 pictures with detailed comments: